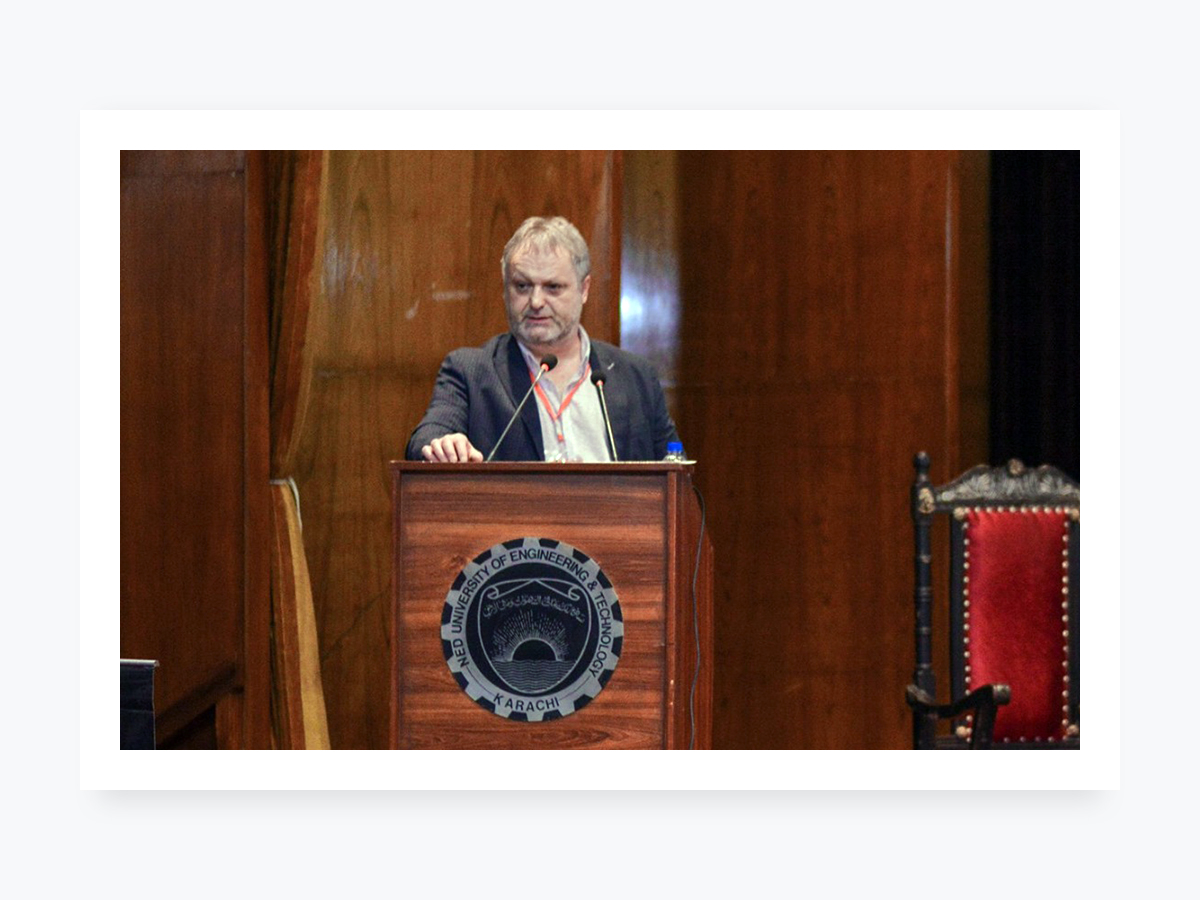

SARS-CoV-2 is Changing the Rules

/ timeSSD /

Until February 2020 the textile and apparel industry were full with new challenges by the increasing customer demands for the sustainable, personalized and functional products.

The orders decreased in quantity by increasing variation of models, showing, not so far, the “Made To Measure” as universal rule. The deadlines were tight and the expected quality higher and higher, the evolution of the fabrics, trimmings and equipment’s asked for the agility of work. It seemed like a new season every week.

The “virus” froze everything for a while. Production lines, shops, malls, planes and plans. Home office, social distancing, healthcare, protection masks, medical textile, numbers with infections was the buzz words.

The world’s reputable persons say the business models are changing after the global lockdown. The fashion industry isn’t it an exception and the nearshoring passed the concept stage. The digitalized product development is a scope, the new value-added models are a must. We learnt very fast to work from home in jobs which allows by the necessary tools. The new style of work with keeping the social distance, the expected reciprocal care, the experience with the fast and huge changes dropping into the unpredictability, are changing the consumers behavior, too, but keeps its expectations and increasing its request for a better experience.

The “Safety” takes first place

Health safety, supply chain safety, products, materials, resources, transportation … financial safety. The circle is closed and in the business the competitiveness is back on top, but more prominently than ever. The pain keeps the lesson in memory. The scale of values should return to normal. The cheap labor can’t be more the main criteria as safety – in all of its aspects – is the first. The number, color, title and diversity of the certificates remains without sense. “Go back to the basics”, as said one of our customers. Competitiveness means productivity in the defined safety conditions, and safety includes quality too.

Digitalized product development requires changes in the RMG engineering and in the behavior of the operators as well, on the way to the digitized manufacturing. The digitized workplaces get a higher importance as part of the social distancing and safety requirements, and even as part of cost reduction. In the same time requires more developed and skilled workers with the essential knowledge necessary for those change process.

The Cloud solutions demonstrated their utility and superiority during the lockdown. This is the best fit for digitizing, collaboration with social distancing, having the highest availability and – in most cases – the highest affordability, like timeSSD®. The required work content optimization by the rapid innovations on the equipment’s, the mandatory re-engineering of the workplaces and methods can’t be done with stop watches or by stone age data from Excel tables. Furthermore, in this “new world” the imposed remote work enlightened the possible cost savings with the transportation and office needs, indeed.

The new market rules increase the competition, not only in “quantity” – as it was usual in the RMG sector before the lockdown – but in quality and innovation, also.

As result the comprehensive solutions are expected for “tomorrow”, on each segment of the supply chain.

The IE professionals has the mission to carry the pressure, to perform the work studies with celerity, to shift the workers skills to the required knowledge, in fact to provide the innovation based added value from the shop floor.

timeSSD® – developed and placed in the Microsoft Azure Cloud – provides:

• Social distancing

Full availability to work with it from anywhere, using a simple internet browser

• Direct cost element

Accurate and predictable cost per unit with its „pay as you go” pricing

• Benchmark

For labor content with MTM-2 based elements

• Clear work methods

Documented on 14 languages with immediate translation

• Decision tool

For the brands with the labor costing support

• Planning tool

Capacity and layout, by the efficiency control features for the manufacturers

• Cooperation

Common database for the team members from different locations

• Transparency

Common platform where brands and manufacturers could exercise the transparency by the integrated method and operation list sharing options

• Liberty

In use or not use, with all-time availability, from anywhere, without user limits, subscriptions and without maintenance costs

• Flexibility

Have your data in PDF, Excel or transferred into your PDM